Welding Project

January, 2024

Last year I bought a used Miller multiprocess welder because I wanted to do more welding especially TIG welding which I have never tried. This welder has been amazing! It makes very clean welds and can be reconfigured to do just about all different types of welding. I built this chair rack for the sailing club. It used to be part of a propane grill and was being used already as a chair rack but it was not working well. There was nothing to hold the chairs in place really, just some planks that were set on the base. I stripped the structure down to the rectangular base with the wheels attached and built up from that. I reused most of the metal. Now everyone at the sail club loves the design!

This is actually the second chair rack I built for them. The last one was pretty simple, kind of a U shape. And I think that one took longer to build, so I think I'm getting better at metal fabrication!

J/24 Project "Bebop"

December, 2023

I bought this boat in November of 2020, then I bought a house a few months later. So this project was sort of on the back burner for months here and there. But I finally sailed her and it was great! This boat was very neglected when I bought her. It sunk a few times from rain water filling the boat. When I stared work, this boat had a few major issues to tackle. First I fixed the holes in the deck that where it was letting in water. Second, I replaced the floor that was taken out due to vermiculite, a mineral that can take on water and get mushy. Third was replacing the main bulkhead, this supports the mast side to side. I also did a lot of cleaning, painting, and other minor repairs.

I am looking forward to warmer weather to get out on the boat more with friends. Right now I am working on the electrical system so I have lights and a bilge pump.

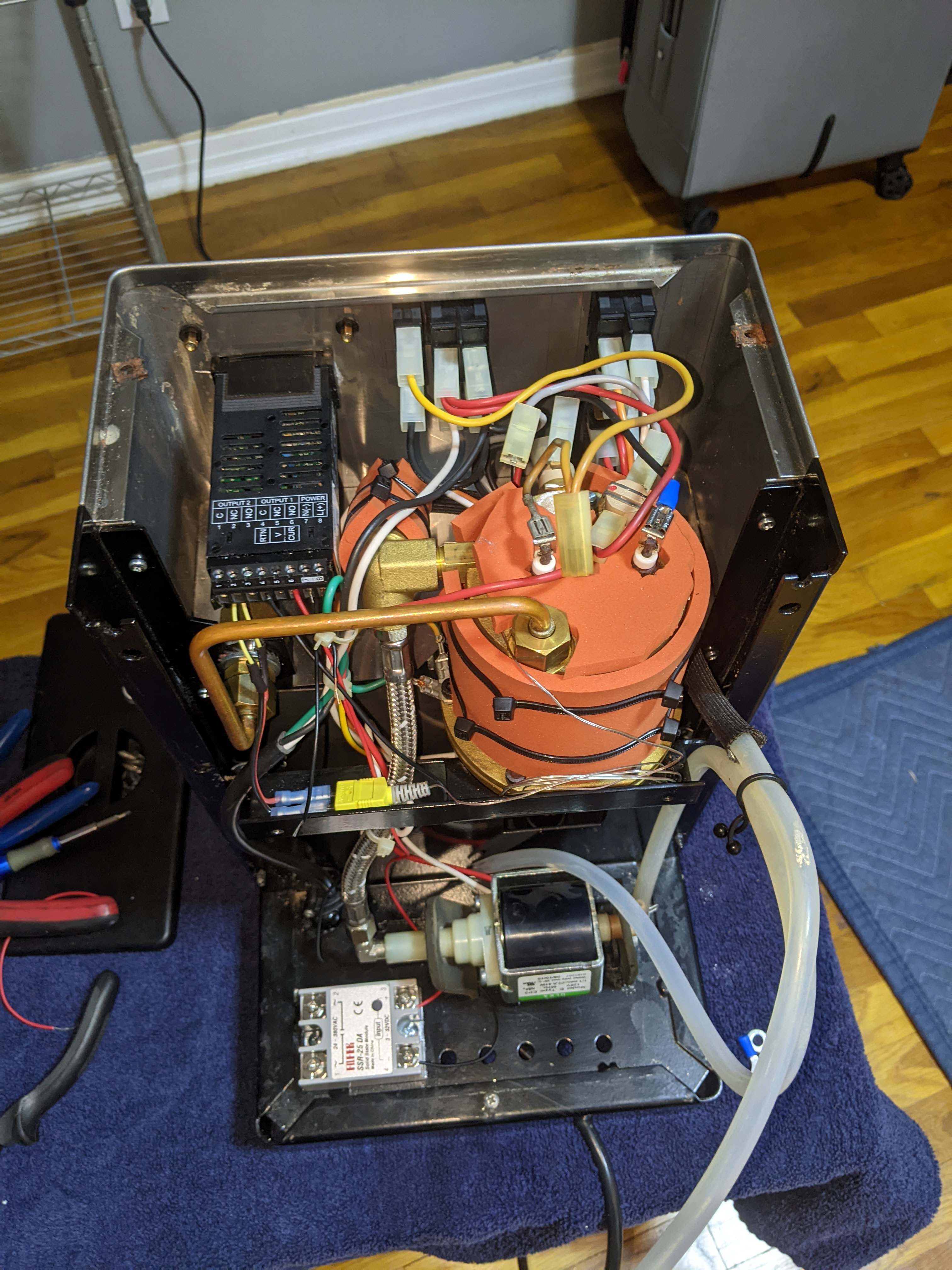

Espresso Machine Project

January, 2023

I decided to take up yet another hobby during the pandemic, espresso brewing. And It turns out that espresso machine modding is a thing. What I did were two common mods, replacing the inaccurate bimetallic thermostat with a PID temperature controller and adding insulation. This allows for tight control of the brew water temp and adjustability. First I dissembled the machine. Second, I installed a solid state relay and cut a rectangular hole for the temp controller. Then, I wired everything up and added a thermocouple under the insulation to measure the heater vessel temp. Lastly, I put the machine back together with the temp controller installed properly and programmed the machine. I really enjoyed this project and learning how this industrial grade temp controller works.

Project Electra Update

November, 2022

After riding around quite a bit on the working bike, I decided it needed an upgrade. This is the new battery! The battery voltage has been increased from 36 volts to 84 volts. The bike is faster and has a longer range. To accomplish this the DC to DC converter had to be replaced to a new one that could accept a higher voltage, as the old one topped out at 45 volts. The DC to DC converter produces 12 volts from the 84 volt battery so that I can run lights and the horn.

Project Electra Is Complete!

Fall, 2021

I am so glad to have fianlly gotten Electra into a complete state after putting off the project for years. I didn't really put off the project that much. I just kind of worked at it with slow pace. There were also other projects, like buying a house, which got in the way. I enjoyed building a wiring harness for the bike. The bike has it's original horn, a fuse box,a new LED head light, and turn signals. The rear light is actually a semi truck light I found on the side of the road. I designed 3D printed covers for both ends of the motor shaft. The bike drives great and is easy to use, just turn it on and go.

I'm already thinking about upgrades. It could use a larger, higher voltage battery. This would require replacing the 12 volt DC to DC converter because the current one maxes out at 40 volts. It could also use a new front fork beacase one is leaking oil and a disk brake would be nice. The drum brakes do not work well. They may need new shoes. One lession learned is I could have gotten a newer bike frame that already had disk brakes. The bike is also missing a battery level and speed gauge but this is not critical becuase I keep it topped up and it only does about 30 MPH.

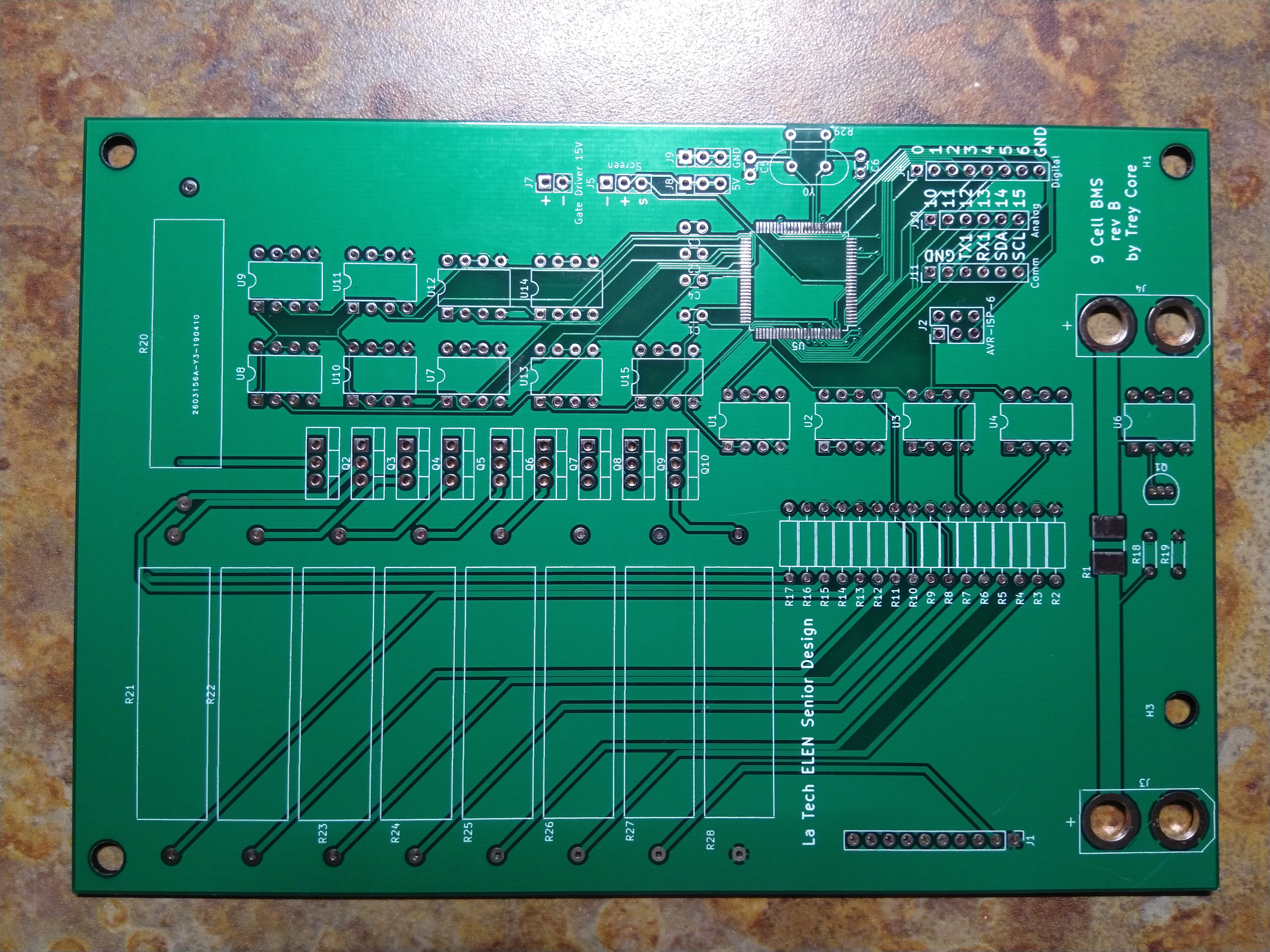

PCB Project: Senior Design

Spring, 2019

I designed this PCB to make things easier during my Senior Design project(Lithium Ion Battery Backup System). This board is the BMS(Battery Management System) and control board. The board senses the voltages from the battery, senses the battery current, and balances the cell voltages. It also disconnects the battery to protect it using external relays. It's very important to have a BMS when using lithium batteries and when the cells are balanced you can get more juice out of them. Unfortunately there were a number of issues involving the board. I had accuracy problems reading the battery voltages using the resistor dividers, seen in the lower middle of the board. The programmer I had could program Atmel 328p chips that the Arduino Uno uses, but not the ATmega2560 chips that the Arduino Mega uses and what I used here. Also the current sense circuit was not usable due to the battery voltage being too high. An isolated current sensor is great for avoiding this issue, which I ended up using externally. I really enjoined designing this board, especially hand routing the thicker, current carrying traces on the left. I would like to try this again using a better current sensor and a high voltage reading ASIC.

I GOT FEATURED ON HACKADAY!

June, 2019

I am overjoyed to be featured on my favorite hacking site! But I did miss when they posted it back in December!

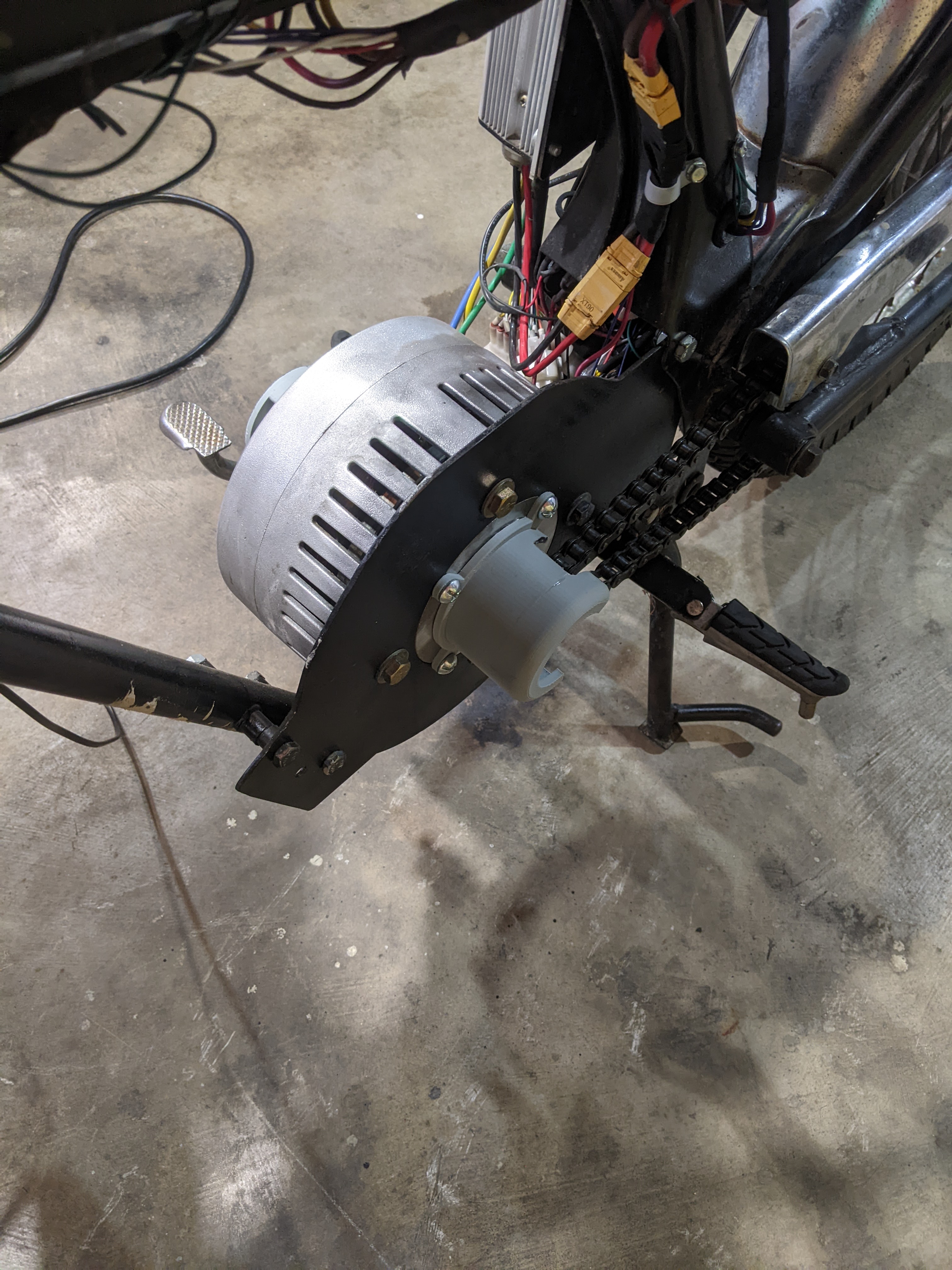

Project Electra Update 1

ongoing, Spring, 2019

I'm very excited on how well this bike is going! So far I've tested the electronics, repainted the frame, and made a mounting plate for the motor. I really like how the motor sits on the bike and there is room to move the motor back an inch or two, closer to the middle of the bike. I might make another plate to fix my measurements that were off a little. There is plenty of plate metal left. The seat I bought on eBay is also very comfortable although I'm not sure if I have it mounted right. Unfortunately, I'm working on half a dozen other projects that are vital to my graduation but I'd really like to get this bike moving under its own power before I move out of town.

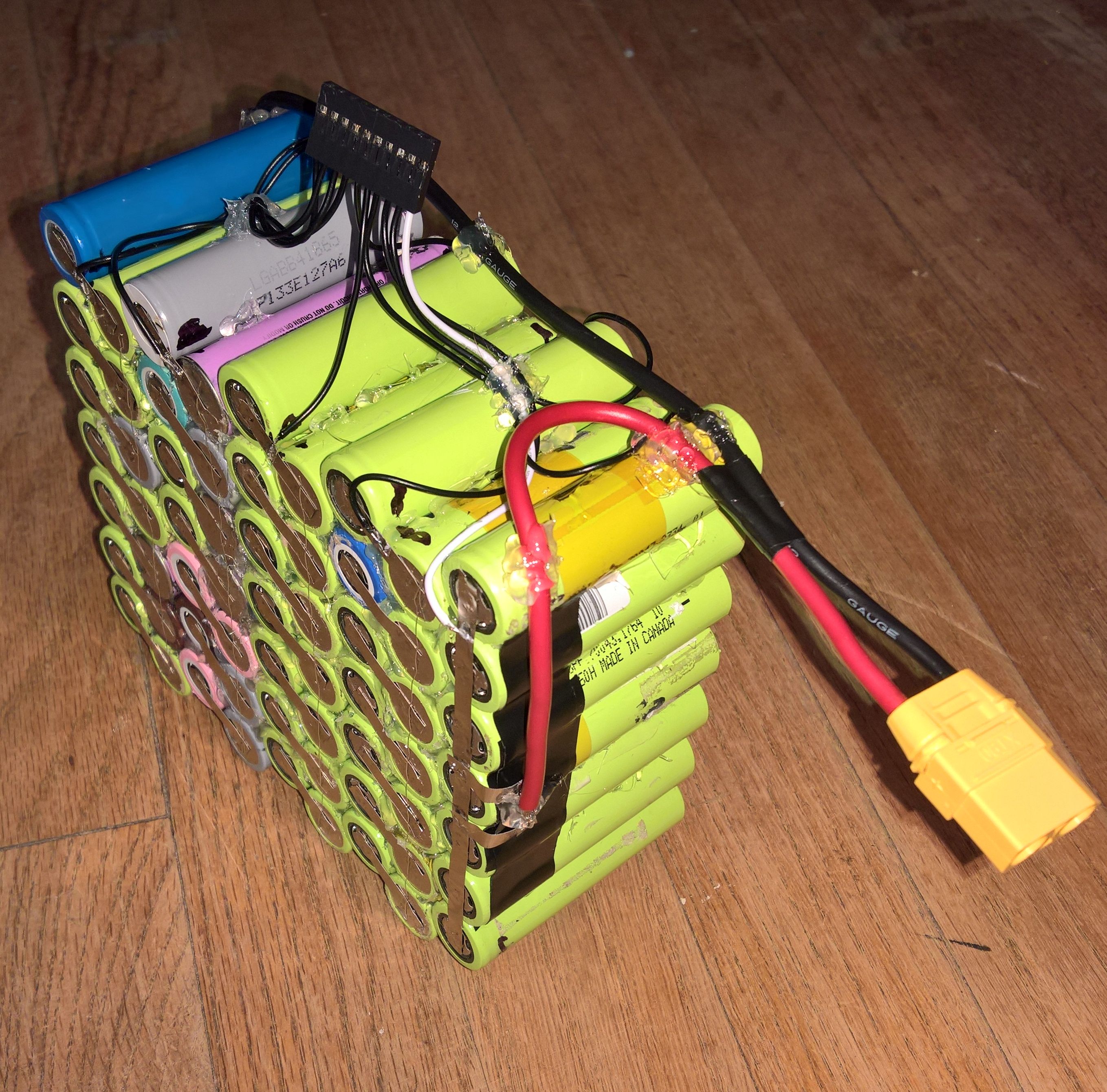

Large Lithium Battery

Complete, Fall, 2018

A classmate an I built this battery for our senior design project which is a battery backup system. The battery has seven cells in parallel and nine cells in series. It features parallel short circuit protection via a small wire connecting the cells in parallel. I have also used the battery a little to test my motor and motor controller for my electric motorcycle project.

Project Razor: Turbo Powered Kids Scooter

Complete, Fall, 2018

I built a lithium battery and a PWM speed controller for this project. The torque is amazing. It will carry me up steep hills with ease but the top speed is rather low. I'm planning on upgrading the rear wheel to a pneumatic one because the hard plastic one makes for a bumpy ride. The reason I built this project was to gain experience in order to build a large, street legal electric motorcycle. I hope to one day work in the field of electric vehicles.

Imgur GalleryMesh Network Project

On Hold, Spring and Fall, 2018

This is a project I started experimenting with during spring 2018 but I stopped over the summer because I wanted to set up the mesh node in Ruston, not Baton Rouge. I wanted to build this project so that the aerospace club could have a live video link from the balloon launch site to our mission control room. The mesh node itself is a Linksys WRT54G router that runs a special third party firmware made by ham radio operators so that it complies with FCC rules. I put it in a weather proof box for outdoor mounting and found an omni-directional antenna for free. Then, this fall, a friend and I set it up on the tower. Now can get a 2000 ft long connection from Wyly tower to my house! This is not an internet link currently. It can be internet enabled, but it can only be used for ham radio related internet traffic.

Unfortunately, I am going to abandon this project for the time being but keep the node up. The person I was testing the equipment with last spring is no longer interested and I want to work on some electric vehicle projects. I would like to revisit this technology in the future and maybe set up a WISP(Wireless Internet Service Provider) business.

Project Electra & Project Razor

Fall, 2018

For the past couple years I've been wanting to build a full size electric motorcycle. And I've just found a good frame to build one on. It's a 1971 Honda CB100, a small motorcycle by today's standards. I think it is a great candidate for an electric powertrain. But I'm going to hold off on it for now even though I have already bought a motor and motor controller. I don't have a title for the bike but I am working to get one. The bike will be no fun a ride if I can't ride it on the road legally.

So I'm going to work on a much smaller project to gain the knowledge I need to build a large electric vehicle. This is Project Razor. It's an electric kids scooter that has a really strong steel frame. I'm going to double the motor size and build a 24 volt lithium battery pack to replace the scooter's lead acid batteries. Building this battery pack will teach me how to build a much larger pack for the motorcycle. This project will be much simpler and less powerful. So if I do mess something us it will be ok. I also want to build a simple motor controller for the scooter.

Hackaday Prize

June, 2018

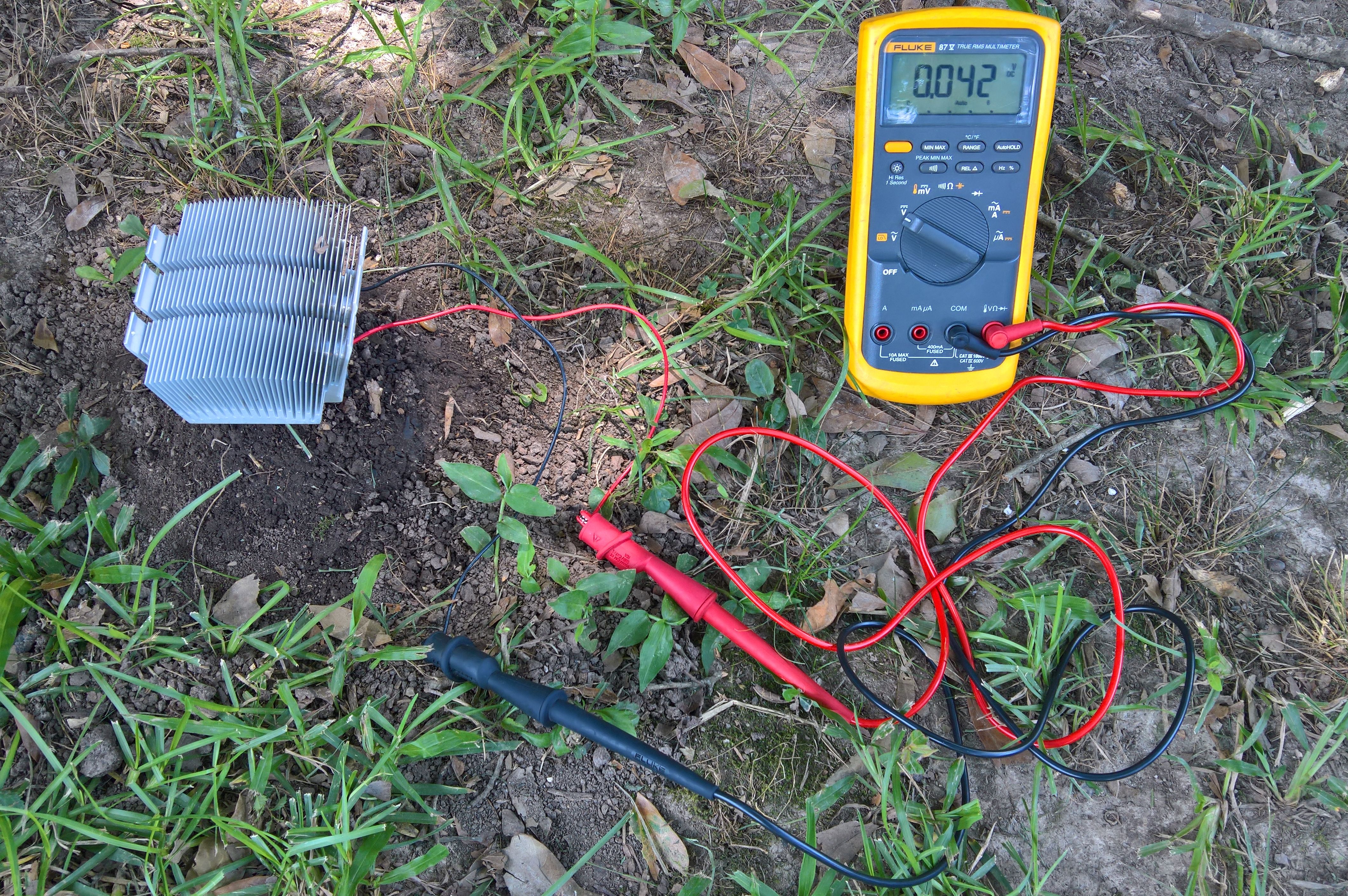

I entered the Hackaday Prize in the energy harvesting category. Hackaday is a online community that embraces DIY projects and home-brew engineering design. Every year they have a large contest called the Hackaday Prize. The theme this year is "Build Hope". This theme resonated with me and I looked at the subcategories to enter into. The category I entered was energy harvesting. Unfortunately I didn't place. But I think my idea was unique. My idea was to build a small scale geothermal generator to power garden lights. This generator uses the temperature differential between the earth and the ambient air to produce DC power directly.

Here is a full description of my project.

My device produces almost half one tenth a volt under the hot summer conditions. Maybe one day I will scale up the design, using multiple Pelier devices to generate a larger voltage. Also, using aluminum instead of steel would be better due to a better heat conduction rate.

Aquaponics: Update

Ongoing, Summer, 2018

My aquaponics system is doing great! The plants grow much faster than growing plants in the ground. This is because they get plenty or water and nutrients from the fish waste.

Aquaponics

ongoing, Summer, 2018

I built a small aquaponics system in my parent's backyard. Aquaponics is a combination of aquaculture, farming fish, and hydroponics, growing plants with water and without soil. The fish produce waste and this waste is a perfect fertilizer for plants. Water is cycled through the system and is filtered in the grow beds on top. The bacteria in the grow beds convert this waste into a form usable to the plants. Then the cleaned water is returned to the fish. A small fountain pump on a timer is used to circulate the water every hour. The only nutrients added into the system is fish food. Right now I have three goldfish in the tank.

The system seems to be working well. The beans on the left were planted from seed and the plants on the right were transplanted. All plants seem to be growing well except the oregano in the middle which is having some trouble. Aquaponics is a sustainable technology because it saves lots of water over traditional farming and it can make protein via harvesting the fish, but in this case I'm not eating my fish. The pump can also be ran off a solar panel. I expect aquaponics to become more and more widespread.

Re-powering a Headlamp

Finished, Spring, 2018

This is a Diamond brand headlamp that ran on 2 AAs. I like to avoid buying AAs so I made it run on a 18650 lithium battery. The battery is charged by a cheap USB battery board that stops charging when the battery is full. Also, the battery is protected from under-discharge by the board. Since the lithium battery provides more voltage than the headlamp is used to via AAs, I added a diode in series with the LED circuit to drop some voltage. I also had to make a new back plate to hold the larger battery and protection board, as the holder for the AAs was too small.

Starting My Motorcycle with a Super Capacitor Bank

Finished, March, 2018

It works! The thing about super caps is they can unleash tons of current instantly, but they lack capacity. So I can only get one attempt to start the bike. This is why after turning the key I quickly hit the starter button. If I didn't, the headlight would could drain the capacitor bank and there would not be enough charge to start the bike. In the future, I may try to build a hybrid lithium and super cap motorcycle battery that would have the benefits of both batteries and capacitors.

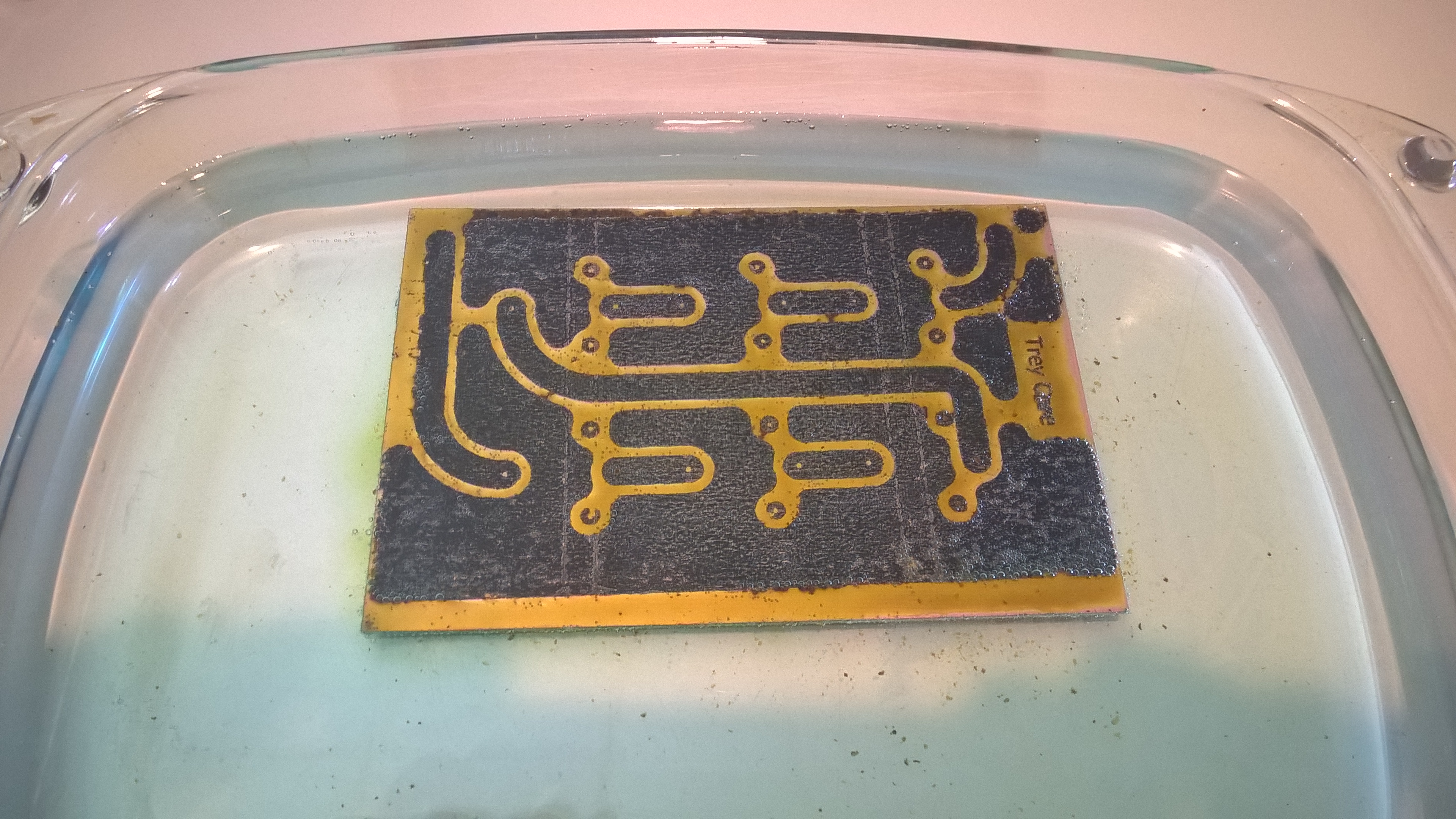

PCB Project

Complete, April, 2017

This was part of a project to build a capacitor bank to replace a motorcycle battery. I used a toner solder mask and then etched the board using vinegar and hydrogen peroxide solution.

Imgur GalleryAutomatic Blinds

Finished, June, 2016

There is a little running gag at my school that involves automatic blinds. It's due to at least one team building an automatic blinds system every year for the Freshman Design Competition. So I can confidently say "I've passed Freshman Design!".

It's become a stale project idea but I wanted to automate my blinds for privacy because my room is at the front of the house and I'm too lazy to get up from my desk. Also, I had an unused gearbox assembly from a printer that I modified by cutting the rod and drilling a hole in the center of the rod. The gearbox had been laying around so I decided to use it along with the H-bridge chip seen on the breadboard. An H-bridge is a really useful circuit used in the control of motors. It allows for speed control and direction reversing of the motor. The code was really simple. First I used some Arduino code to sense and recored the two up and down channel codes that the remote was sending per button press. The, I wrote another program to pulse the motor one direction when the code was received from the remote. I wanted. Since I had all the parts that I needed, this project came together in a couple hours. It has been working unmodified from its original state for two years as of June 2018!

Motorcycle Project

Ongoing project, May, 2016

My 1993 Yamaha XJ600

During my spring quarter of 2016 at Tech, I decided to get a run down motorcycle on Craglist and fix it up.

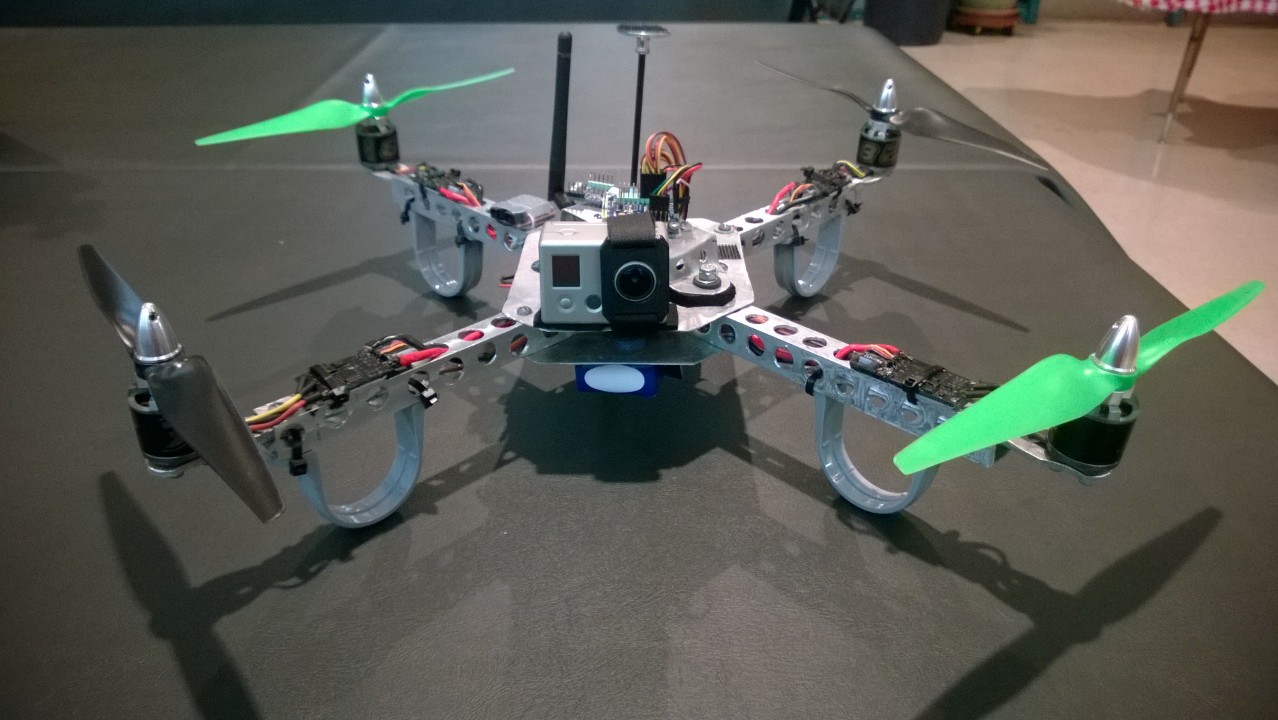

Imgur GalleryMy First Drone

Completed, Fall, 2014

This drone was built from aluminum and flew really well. It was a bit hard to fit everything on board though. In the final version, I took off the plastic and wires that came with the motor controllers, then sprayed them in liquid electrical tape and moved them closer to the motors. This was to reduce bulkiness and save weight. It got about 12 minutes of flight time. I ended up trying a few different types of landing gear for this drone. The best were gray plastic conduit holders from HomeDepot, which is also were I got the aluminum. The landing gear in the bottom picture was made of plexyglass that I had laser cut using an AutoCAD drawing I made. These legs ended up breaking due to me using thin plexyglass that was very brittle.

This drone also uses a special Go Pro holder that fits over the lens of the camera. I designed and 3D printed this part myself.

About Me

Welcome to my blog! I love to learn how stuff works, take stuff apart, and then then build new inventions from the scraps. When I'm not building stuff I like to learn about science and engineering on the internet. Here's a few of the projects I've worked on.